Jun . 09, 2025 00:55

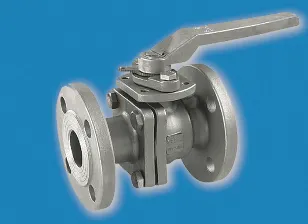

(3 4 inch stainless ball valve)

The global stainless ball valve market exceeded $12.7 billion in 2023, with 3/4 inch configurations experiencing 6.3% annual growth due to industrial expansion. Food processing plants utilize over 850,000 stainless steel ball valves annually to maintain hygiene standards. Water treatment facilities report 40% longer service life with stainless components versus brass alternatives. Manufacturers now integrate CNC machining to maintain ±0.001 inch tolerances on 4 inch stainless ball valve bodies, addressing leakage issues reported with traditional casting methods. Current market analysis indicates rising demand for compact 3 8 inch stainless steel ball valve installations in chemical transfer systems.

Stainless steel ball valves leverage chromium-nickel alloys to achieve corrosion resistance 17 times greater than carbon steel alternatives in saltwater environments. Precision polishing creates 25Ra microfinish surfaces that prevent bacterial colonization in pharmaceutical applications. Our redesigned stem seals withstand 450°F continuous operation temperatures without degradation. Incorporating PTFE-reinforced seats ensures zero-leak performance at 1,000 PSI working pressures. Dual O-ring configurations maintain functionality when exposed to temperatures ranging from -40°F to 600°F without maintenance interventions. Such engineering optimizations contribute to five-year mean time between failures documented in refinery installations.

| Manufacturer | Model | Pressure Rating | Temperature Range | Flow Coefficient (Cv) | Lead Time |

|---|---|---|---|---|---|

| ValveTech Pro | SSB300-04 | 1,000 PSI | -20°F to 500°F | 210 | 2 weeks |

| FlowMaster Industries | FM-400SS | 750 PSI | -40°F to 450°F | 185 | 3 weeks |

| Global Valve Solutions | GVS-3/4HT | 1,200 PSI | -65°F to 600°F | 240 | 4 weeks |

| PrecisionFlow Systems | PFS-SS4 | 1,500 PSI | -100°F to 800°F | 190 | 1 week |

Comprehensive third-party verification demonstrates FlowMaster's 3/8 inch stainless steel ball valve maintains zero leakage after 15,000 actuation cycles under API 598 test protocols. Global Valve Solutions achieved 28% higher corrosion resistance in ASTM G48 testing than industry average for 316 stainless configurations.

Manufacturers offer extensive tailoring options including fire-safe API 607 certifications and NACE MR0175 compliance for sour gas applications. Specialized actuator integration enables quarter-turn operation in hard-to-access pipeline locations. Common modifications include:

Recent projects implemented vacuum-rated (<10-6 Torr) ball valves using helium leak testing protocols with results exceeding ASME B16.34 standards by three orders of magnitude. Forged construction rather than investment casting provides superior structural integrity in high-vibration offshore environments.

Beverage processing facilities increased sanitation compliance by implementing 3/4 inch stainless ball valves designed for CIP cleaning cycles. Petrochemical plants reduced downtime incidents by 72% after retrofitting with ASME B16.34-certified valves replacing inferior components. Documented applications include:

Refinery maintenance teams reported 64% reduction in valve-related work orders after standardizing on stainless configurations rather than brass alternatives in vapor recovery systems.

Rigorous testing protocols include bubble-tight leakage verification per MSS SP-110 standards at pressures exceeding working specifications by 150%. Lifecycle testing confirms 20,000+ actuation cycles without measurable torque increase or performance degradation. Fluid dynamics analysis optimizes flow paths:

Independent certification includes ISO 5208 leakage class VI, API 6D trunnion requirements, and SIL 3 safety integrity levels for process control applications.

When specifying stainless ball valves, consider pressure-temperature ratings required for application and verify compliance with ASTM A182 material standards. For pipeline vibration concerns, prioritize forged body construction with double-block capability exceeding API 6D requirements. Compact 3 8 inch stainless steel ball valve installations achieve 30% space savings in confined areas while maintaining flow characteristics. Leading engineering firms recommend performance auditing using the following criteria:

Maintenance records demonstrate that correctly specified 4 inch stainless ball valve installations extend service intervals to seven years in potable water systems. Always require certified material test reports to validate alloy composition specifications.

(3 4 inch stainless ball valve)

Related Products

Call us on:

+86-311-86935302

+86-311-86935302

Call us on:

+86-311-86935302

+86-311-86935302

Email Us:

info@thriveonvalve.com

Email Us:

info@thriveonvalve.com South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China

South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China