May . 12, 2025 11:41

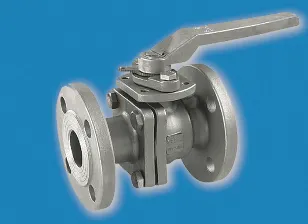

When it comes to industrial applications that require fluid control, selecting the right ball valve flange type is crucial. Whether dealing with water, oil, gas, or chemicals, a high-quality ball valve flange ensures smooth operation, durability, and safety. But with so many options available, how do you choose the best one? This guide will help you understand the key features, benefits, and factors influencing the flange type ball valve price, with a focus on the best options from China flange ball valve manufacturers.

A ball valve flange type is designed to provide a tight seal, minimizing leaks and enhancing efficiency in various industrial processes. But what exactly defines a high-quality ball valve flange?

One of the most critical aspects of a ball valve flange type is the material used in its construction. Stainless steel, carbon steel, and cast iron are some of the most popular materials. Stainless steel offers excellent corrosion resistance, while carbon steel is known for its strength. Choosing the right material ensures longevity and reliability.

When selecting a china flange ball valve, always look for manufacturers that adhere to international standards like API, ANSI, DIN, and ISO. A well-manufactured ball valve flange provides smooth operation and can withstand extreme pressure and temperature conditions.

The effectiveness of a flange type ball valve largely depends on its sealing mechanism. Options include soft-seated and metal-seated designs. Soft-seated valves use materials like PTFE for enhanced sealing, while metal-seated valves offer durability under high temperatures and abrasive conditions.

Not all ball valve flange types are suited for every industry. Industries like oil and gas, chemical processing, power plants, and water treatment require different specifications. Understanding your operational needs will help you select the perfect ball valve flange for your business.

When purchasing a flange type ball valve, understanding the pricing structure can help you make an informed decision. The flange type ball valve price varies based on multiple factors, including materials, pressure ratings, and customization options.

High-quality stainless steel china flange ball valve products tend to be more expensive than carbon steel or cast iron options. However, investing in durable materials reduces long-term maintenance costs.

The larger the ball valve flange type, the higher the cost. Additionally, valves designed for high-pressure applications come at a premium. Standard pressure ratings include 150LB, 300LB, and 600LB, with prices increasing as the rating goes higher.

A ball valve flange produced by an ISO-certified manufacturer generally costs more due to the strict quality control measures in place. However, the reliability and performance benefits outweigh the initial investment.

If your application requires special coatings, actuators, or automation capabilities, expect to pay a higher flange type ball valve price. However, customized china flange ball valve solutions can improve operational efficiency and lifespan.

Buying directly from china flange ball valve manufacturers can reduce costs significantly compared to purchasing from intermediaries. Bulk purchases often come with discounts, making it more cost-effective for large-scale projects.

China has become a leading global supplier of ball valve flange products, offering cost-effective and high-quality solutions. But what makes a china flange ball valve a great choice for industries worldwide?

Chinese manufacturers offer some of the most competitive flange type ball valve prices due to their efficient production processes and access to high-quality raw materials.

Many china flange ball valve manufacturers use cutting-edge technology to produce precision-engineered ball valve flange products that meet international standards.

Whether you need a standard ball valve flange type or a fully customized solution, Chinese manufacturers offer a wide range of configurations to meet specific industrial requirements.

With a strong global supply chain, china flange ball valve manufacturers can ship products worldwide quickly and efficiently. Many also offer after-sales support, ensuring smooth operation post-installation.

A well-manufactured ball valve flange from China ensures long-term reliability, reducing maintenance and replacement costs. Investing in a high-quality china flange ball valve can significantly improve operational efficiency.

A ball valve flange type provides excellent sealing performance, ease of installation, and durability. It is ideal for applications requiring frequent operation and minimal leakage. Additionally, the flanged connection allows for easy maintenance and replacement.

Selecting the right ball valve flange depends on factors such as pressure rating, material, sealing type, and application requirements. Consider whether you need a soft-seated or metal-seated valve and choose a material that suits your operating environment (e.g., stainless steel for corrosion resistance).

The flange type ball valve price varies due to differences in materials, manufacturing processes, certifications, and customization options. Premium materials and precision engineering lead to higher costs but ensure better performance and longevity.

Yes, china flange ball valve products are highly reliable when sourced from reputable manufacturers. Many comply with international standards and undergo rigorous quality testing, making them a cost-effective and durable solution.

Regular maintenance includes inspecting for leaks, lubricating moving parts, and checking for wear and tear on seals. Proper installation and periodic servicing ensure a longer lifespan and optimal performance of your ball valve flange type.

Related Products

Call us on:

+86-311-86935302

+86-311-86935302

Call us on:

+86-311-86935302

+86-311-86935302

Email Us:

info@thriveonvalve.com

Email Us:

info@thriveonvalve.com South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China

South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China