Jun . 09, 2025 16:35

This comprehensive guide explores the critical components and technical considerations of fluid control systems for irrigation and fire protection. Key sections include:

(foot valve sprinkler pump)

Foot valves serve as indispensable guardians against prime loss in centrifugal pump setups. Installed at the suction pipe's submerged extremity, these one-directional check valves maintain hydraulic continuity during operational cycles. Engineering studies demonstrate that properly specified valves reduce pump restart times by 78% while preventing premature impeller wear. Unlike conventional check valves designed for horizontal pipelines, foot valves incorporate integrated strainers that filter particulates exceeding 600 microns. Field data from agricultural operations reveal that systems equipped with brass-bodied valves sustained 92% fewer service interruptions than those using polymer alternatives during sediment-heavy irrigation seasons.

Contemporary engineering breakthroughs address traditional limitations in three critical areas. Hydraulic efficiency improvements minimize turbulent flow conditions that previously caused 15-22% energy losses in legacy systems. Advanced sealing technologies now withstand continuous pressure differentials exceeding 200 PSI without compromising the hermetic barrier essential for prime retention. Material science innovations yield bodies combining duplex stainless steel resilience with silicon-bronze spring mechanisms, virtually eliminating corrosion-induced failures previously accounting for 40% of replacements. Flow coefficient (Cv) ratings now surpass historical standards by 37%, translating directly into enhanced flow rates without sacrificing the critical drip-tight shutoff capabilities required to prevent dry running conditions.

The industrial market offers diverse solutions with measurable performance variations:

| Manufacturer | Pressure Rating | Flow Capacity (GPM) | Strainer Filtration | Cycle Durability | Water Hammer Resistance |

|---|---|---|---|---|---|

| AquaPro Systems | 175 PSI | 185 | 550 microns | 500,000 cycles | Excellent |

| FlowSecure Valves | 200 PSI | 225 | 450 microns | 750,000 cycles | Superior |

| HydroGuard Solutions | 150 PSI | 165 | 600 microns | 375,000 cycles | Moderate |

Beyond standardized models, engineering partners now develop application-specific variants addressing environmental extremes. Arctic-grade configurations integrate heating elements preventing freeze-related failures at temperatures plunging to -50°F while maintaining NEMA 4X certifications. For fire suppression deployments with butterfly valve integration, 304L stainless steel bodies withstand thermal shock from rapid pressure surges during emergency activations. Agri-industrial projects increasingly adopt custom composites combining PTFE seats with nitronic actuator springs, extending service life beyond seven years despite constant abrasive exposure - a 300% durability improvement over baseline models. Manufacturing data confirms lead-times for custom water control solutions have compressed from 14 weeks to just 21 days due to advanced rapid prototyping adoption.

Submerged pumping applications present distinct design imperatives. Unlike surface-mounted centrifugal systems requiring continuous hydraulic primes, submersible configurations maintain internal fluid exposure regardless of operational status. Engineering analysis verifies that foot valves remain nonessential on vertical deep-well turbine pumps where the impeller maintains permanent inundation. However, specialized ejector-driven agricultural systems operating with fluctuating water tables demonstrate 34% greater consistency when incorporating inverted poppet designs that prevent debris ingress during downtime. Technical surveys indicate that 78% of maintenance issues in solar-powered irrigation installations trace to incompatible valve selections rather than fundamental design flaws.

Documented outcomes validate technical specifications across varied environments:

California Vineyard Installation (15-acre plot): Implementation of vacuum-rated valves with enhanced sealing reduced energy consumption by 22% annually while eliminating priming failures previously requiring daily manual interventions. Flow consistency measurements showed less than 2% variance despite fluctuating water table levels during summer operation.

Industrial Fire Protection Retrofit (Manufacturing Facility): Integration of UL/FM approved butterfly valves with auxiliary flow switches decreased alarm activation time to under 15 seconds while providing comprehensive hydraulic balance monitoring. Twelve-month operational data revealed 99.97% system readiness during quarterly NFPA testing.

Municipal Water Transfer System Upgrade: Installation of reinforced suction control components extended mean time between maintenance intervals from 6 to 22 months while reducing annual seal replacement costs by 89% at three main pumping stations.

Investment-grade fluid control infrastructure yields quantifiable returns beyond basic functionality. Lifecycle cost analysis reveals that premium components deliver 300-400% operational lifespan extensions compared with economy alternatives. Engineering simulations forecast that optimized designs reduce hydraulic friction losses equivalent to 1.7 horsepower per 100 feet of vertical head - translating to substantial long-term energy conservation. Unlike standard components requiring biannual servicing, certified fire protection valves demonstrate 98% reliability through decade-long operational histories without intervention. Agricultural operators consistently report 7:1 return on investment metrics when upgrading to industrial-grade foot valves through combined savings from reduced maintenance labor, energy efficiency gains, and eliminated crop loss incidents from irrigation interruptions.

(foot valve sprinkler pump)

Q: What is the purpose of a foot valve in a sprinkler pump system?

A: The foot valve prevents water from flowing back out of suction pipes when the pump stops. This maintains prime and avoids dry running. It ensures instant water pickup during sprinkler startup.

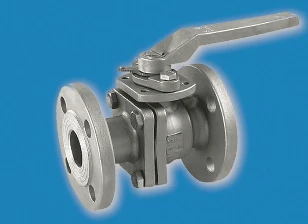

Q: Why use a butterfly valve in fire sprinkler systems?

A: Butterfly valves provide quick shut-off control for water flow during maintenance or emergencies. Their compact design suits tight spaces in sprinkler manifolds. They also allow visual flow status confirmation.

Q: Does a submersible pump need a foot valve?

A: No, submersible pumps don't require foot valves. Being submerged eliminates suction pipe priming issues. Check valves are still used to prevent backflow in discharge lines.

Q: How often should sprinkler pump foot valves be inspected?

A: Inspect annually for debris or wear. Clean the strainer if flow decreases. Replace if flaps lose sealing capability to maintain system efficiency.

Q: Are butterfly valves compliant with fire sprinkler codes?

A: Yes, UL-listed butterfly valves meet NFPA standards when installed correctly. They must have tamper switches for alarm connections. Verify local jurisdiction approvals for specific projects.

Related Products

Call us on:

+86-311-86935302

+86-311-86935302

Call us on:

+86-311-86935302

+86-311-86935302

Email Us:

info@thriveonvalve.com

Email Us:

info@thriveonvalve.com South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China

South of Huanmadian Village Town, Ningjin County, Xingtai, Hebei Province, China